In the early phases of my mycelium biocomposite development project, I relied on plastic containers and cardboard to create molds. However, after several iterations, I realized the need for a more robust, precise, and efficient method to produce molds, especially as the demand for multiple molds within a short timeframe grew. This realization led me to explore the world of 3D printing.

A generous friend lent me an Ender 3 3D printer, which opened up a new realm of possibilities. My task was to procure PLA filament and learn the basics of 3D modeling and printing. Given the time constraints and the relatively simple requirements for mold designs, I opted to use Tinkercad, a user-friendly 3D modeling tool. Once I was comfortable with Tinkercad, I used Ultimaker Cura to slice my models and prepare them for printing.

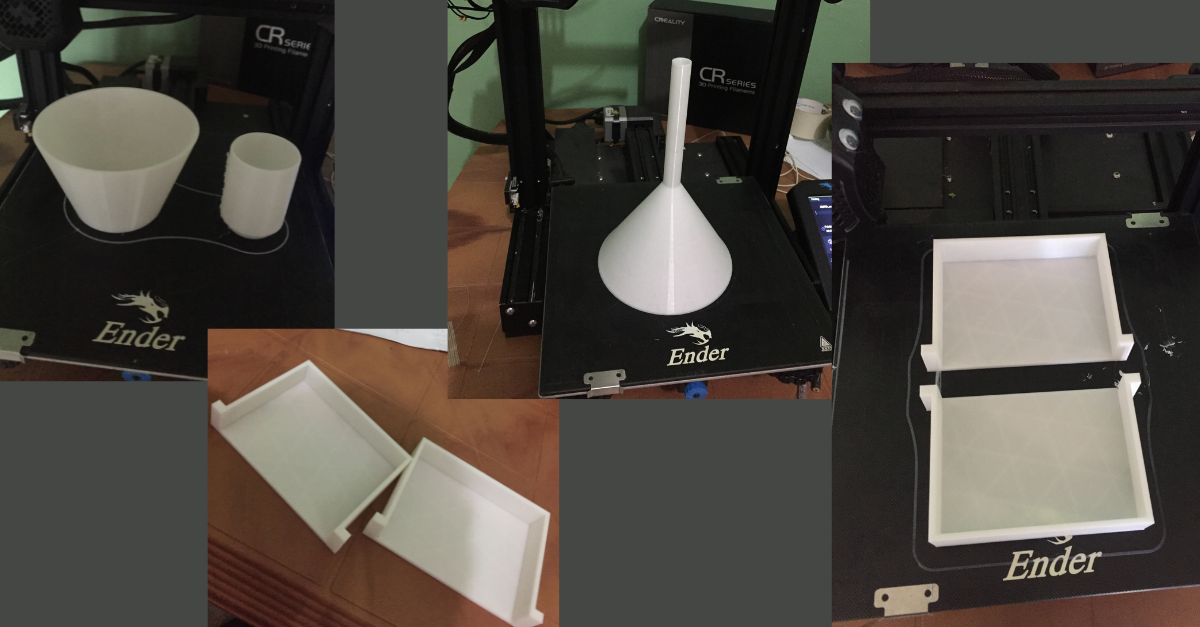

The process involved saving the sliced models onto a memory chip, setting up the printer with the PLA filament, and calibrating the machine. I decided to let the printer run overnight, and by morning, I had successfully produced several molds. These molds were then used in various mycelium biocomposite projects, enabling the creation of unique shapes and designs.

This project was particularly fascinating because I started with little knowledge of 3D printing. With help from friends, colleagues, and a plethora of YouTube tutorials, I quickly got up to speed. While I didn’t become an expert, my approach was pragmatic: find the simplest tools, leverage available expertise, and achieve the project’s goals efficiently. In that context, this project was incredibly rewarding and showcased the power of learning by doing.

If you’re interested in exploring mycelium biocomposites or 3D printing, I’d love to connect and share insights. This journey has shown me the value of combining traditional and digital fabrication techniques to innovate in sustainable materials.